MADE-TO-ORDER. READY WHEN YOU ARE – EVEN 50 DAYS LATER

Our made-to-order, preimpregnated liners offer an industry-leading 50-day pot life — giving you the flexibility to plan ahead, reduce waste, and optimize operator time in the field by eliminating on-site mixing and prep.

PREIMPREGNATED LINERS WITH 50 DAYS OF FLEXIBILITY

- No on-site resin mixing required: Comes pre-impregnated and ready to install in the next 50 days

- Ready-to-install convenience: Available in a wide range of diameters and lengths, ensuring zero material waste

- Custom Lengths Available: Liners can be ordered pre-cut to your project’s exact requirements to eliminate waste and preparation time.

- Simplifies Inventory Management: Convenient kit format reduces the need to stock multiple separate components.

- Ready-to-Use: No need for field wet-out – simply load and invert.

- Engineered-Sealed Liner Design: A product that cities can put their trust into.

STEAM CURING MADE SIMPLER

- Everything You Need: Includes preimpregnated liners, calibration tubes, resin packs, and accessories to quickly reload your inversion setup

- Seamless Compatibility: Designed to work seamlessly with any steam curing inversion kit

- Fast-Curing Options: Offers steam-curable liners that can be cured in as little as one hour for minimal downtime.

- Extended Pot Life: Preimpregnated liners with up to 50 days of pot life, giving you unmatched flexibility in scheduling installations.

ENVIRONMENT-FRIENDLY

- No VOCs or harmful vapors during installation: Cleaner, safer work environment for workers and nearby residents.

- Compatible with Eco-Friendly Worksite Practices: Supports practices like centralized operations, zero on-site mixing, and better surplus material management.

- Reduced Material Waste: Thanks to its long shelf life, less resin is discarded compared to traditional resins that cure quickly if not used.

- Less Unnecessary Transportation: Reduce round trips for preparation or material replacement and therefore lowering the carbon footprint of transportation.

- Rigorous scientific testing: Our liners have been proven to block root intrusion and water infiltration for over 50 years—performance that provides long-term peace of mind.

ADVANTAGES OF THE CUREFLEX LATENT RESIN

- Exceptional Logistical Flexibility: Ideal for projects with unexpected delays, schedule changes, or limited access.

- Reduced Waste: Designed to work seamlessly with any steam curing inversion kit

- Optimized Resource Use: Saves labor on-site: no need for on-site resin mixing, reducing the need for technical staff and specialized equipment.

- Consistent, Controlled Quality: Factory pre-impregnation ensures uniform, precisely controlled saturation and enhances long-term mechanical performance and liner adhesion.

- Geographical Flexibility: Can be shipped worldwide and stored until use—even in remote areas or unpredictable climates.

FLEXURAL STRENGTH

PipeBolster | 5,800 psi

Minimum Value | 4,500 psi

FLEXURAL MODULUS

PipeBolster | 373,762 psi

Minimum Value | 250,000 psi

APPLICATIONS

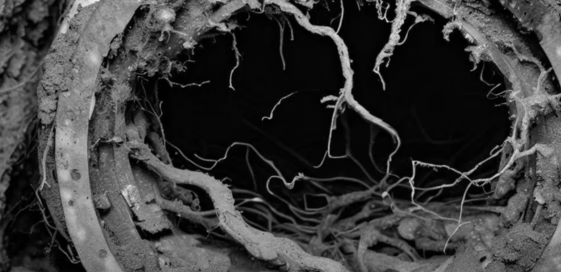

ROOT INTRUSIONS

Stop backflows caused by the blockages generated by root intrusions and return to operation quickly.

CRACKS

Get rid of cracks and extend the lifespan of your drains without having to excavate.

HOLES

Patch drain holes causing leaks and infiltration fast and efficiently.

TOILET BENDS

Quickly fix leaking toilet bends without having to perform costly and cumbersome excavations.